Content:

Some summer residents believe that a shredder is an extra waste of money, and you can do without this device. The need for this unit on the farm is obvious. Shredded grass rotts faster in compost and is easier for the stomachs of small pets.

A chipped branch is an excellent mulch for horticultural crops. It can also be used to light up stoves. If you can't afford a factory unit, you can make your own garden shredder.

Varieties of garden shredders

The principle of operation of the shredder is simple and akin to a kitchen meat grinder. It is enough to put garden waste into the hopper and turn on the engine. The motor drives the shaft with cutting elements. As a result, the gardener receives a shredded plant.

There are various models of crushers on sale. They have a lot of advantages, but for some, buying a shredder is unacceptable due to the high price. But a home craftsman may well make a garden chopper for grass and branches with his own hands, using improvised materials and machine engines for this.

The attachments are divided into 3 categories: motor power, its type, and also the type of grinder.

As for the latter, several types are considered:

- universal knife;

- milling cutter - for hard wood;

- hammer type - for the disposal of thin stems;

- turbine - for thick branches;

- roll - grinds the shoots of bushes and trees;

- line trimmer - cuts soft debris.

Most summer residents prefer a versatile option that can chop both grass and solid waste.

By the type of engine, gasoline and electric are considered. Moreover, each of them has its own pros and cons.

Shredder motor types

| Motor | Benefits | disadvantages |

|---|---|---|

| Petrol | · Mobile; | · Heavy and bulky; |

| · Powerful; | · Is a source of harmful emissions | |

| Handles hard branches easily | ||

| Electric | · Has a low weight; | · Electricity is required; |

| · Easy to operate; | Inferior in power to fuel | |

| Environmentally friendly |

The ability to recycle this or that garbage from the garden is determined by the capacity of the unit. Before creating a homemade chipper (another name for a grinder), they determine its purpose and select an engine with a suitable power.

Power types

| power, kWt | Capabilities |

|---|---|

| 1.5 | Grass and a twig no thicker than 20 mm are crushed |

| 3,5-4 | The unit is capable of grinding branches up to 40 mm |

| 6 | Easily handles large timber 100-150 mm thick |

You should also pay attention to the type of drive. This could be the motor shaft on which the cutting knives are attached. A belt or chain drive is also used.

It is easy to create a chopper of grass and branches for giving with your own hands from the most unexpected materials.

The easiest ways are to use unnecessary household appliances:

- an interesting option is obtained if a vacuum cleaner, a working grinder and knives from a lawn mower are involved in the shredder;

- if the washing machine has become unusable, take its working motor and body, supplementing it with an old saw, a bucket and fasteners;

- you can make a chopper based on an electric drill, a metal bucket with holes and a stool.

Such inventions from the local Kulibins are interesting and are quite suitable for small volumes of raw materials. If you want to create a more serious shredder, while using a simple design, you should consider a chipper with a belt drive and circular knives mounted on the motor shaft.

Manufacturing guide

It should be noted right away that even the simplest design will not work if the summer resident does not have locksmith skills. You will have to work not only with your hands, but also with your head - a drawing is taken as a basis, you need to be able to read it.

When the scheme is selected, they are engaged in the procurement of the necessary materials and parts. Before assembling the country shredder, all work is divided into stages.

Engine selection and belt drive calculation

For the selected type of shredder, the number of motor revolutions does not matter - the drive itself will give the required rotation speed. Therefore, you should not take an engine too powerful.

The wood chipper will still operate normally at 1500 rpm. The best option for a summer resident is 2.5-3.5 kW. For mini-tractors and motorcycle blocks, you should choose an engine with a capacity of 5-6 hp.

Sample calculation

Presumably the farm has a 2800 rpm engine. They decided to connect a branch crusher to it. But the optimal solution is half the number of revolutions (1400). It is possible to reduce the parameter if the diameters of the shafts differ by 2 times. In other words, for the driving pulley, the size should be 100 mm, for the driven one - 200.

Preparation of materials

To make a garden electric branch shredder with your own hands, it is not necessary to purchase new materials. For this, the means at hand are quite suitable.

A good owner in a barn will always have several types of rolled metal needed to make a frame:

- profile pipes 40x40 mm or round pipes 32-48 mm;

- corners of 35 mm, welded by a box, and single-shelf multi-shelf with parameters 50-63 mm;

- channel bars No. 6.5-10.

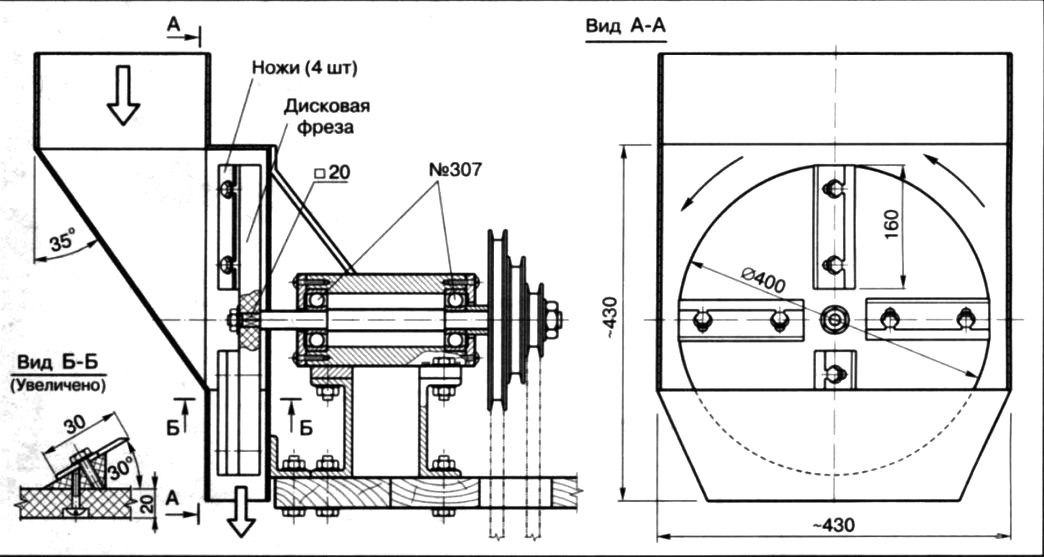

To make a shredder, you will have to buy from 20 to 25 circular saws, which will provide a working part with a width of 80 mm. The set for the discs will need delivery washers with a diameter of 20 mm.

For the chipper, they also take:

- shaft with bearings;

- sheet metal 5 mm for the casing and 1-2 mm for the hopper;

- steel circle (its parameters are selected based on engine power);

- bolts with nuts M12-16 (required for fasteners).

Having prepared everything you need, you can start assembling the unit.

Frame making

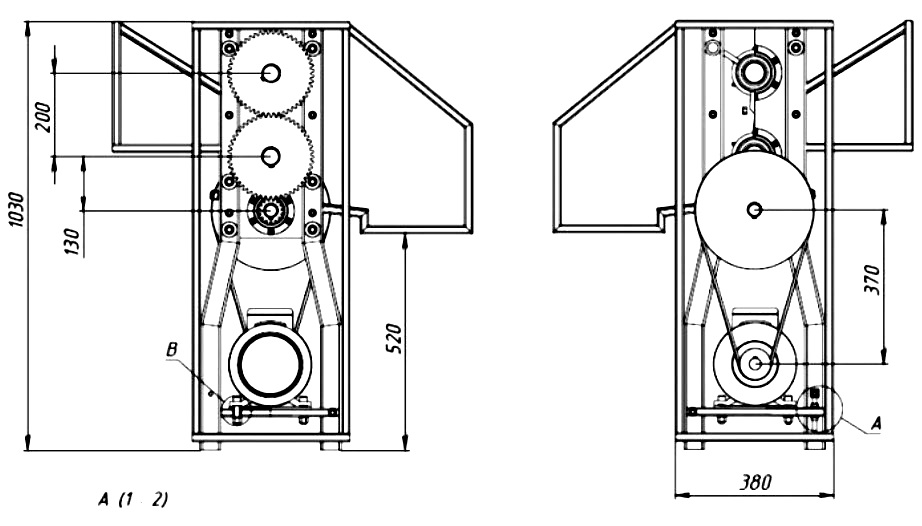

Having prepared in advance a drawing of the future device, for a start, a frame is made to which the nodes will be attached.

So that chopping branches does not get tired, when welding corners (or pipes), you need to adhere to the following recommendations:

- the height of the frame is matched to the height of the worker;

- for the stability of the structure, its width must be at least 0.5 m;

- cross members welded to the uprights will ensure the rigidity of the bed;

- for the mobility of the unit, it is recommended to put the frame on wheels and attach a handle.

Chopper assembly

To make the device reliable and safe in operation, the following algorithm is followed during assembly:

- the saws are strung on the shaft, delimiting them with washers, and tightened from 2 sides with nuts;

- having lubricated the bearing cages, the latter are pressed onto the shaft, then into the outer housings;

- the node is screwed to the frame with bolts into pre-prepared holes;

- a flywheel and a pulley are installed on the ends of the shaft, ensuring reliable fastening;

- the counter knife (steel plate) is placed close to the saw teeth;

- install the main gear and motor;

- put on the belt, pulling it as tight as possible.

The hopper should be welded to the frame in such a way that the branches are fed relative to the cutting tool at a perpendicular angle.

The advantages of a homemade option

Do-it-yourself garden shredder of branches allows you to significantly save the family budget, eliminating the purchase of an expensive unit. You will not have to spend money on hired sawers - a home-made device is convenient to use.